MILADO: MultIwavelength LAser for fast DiagnOstic in biomedical and manufacturing applications

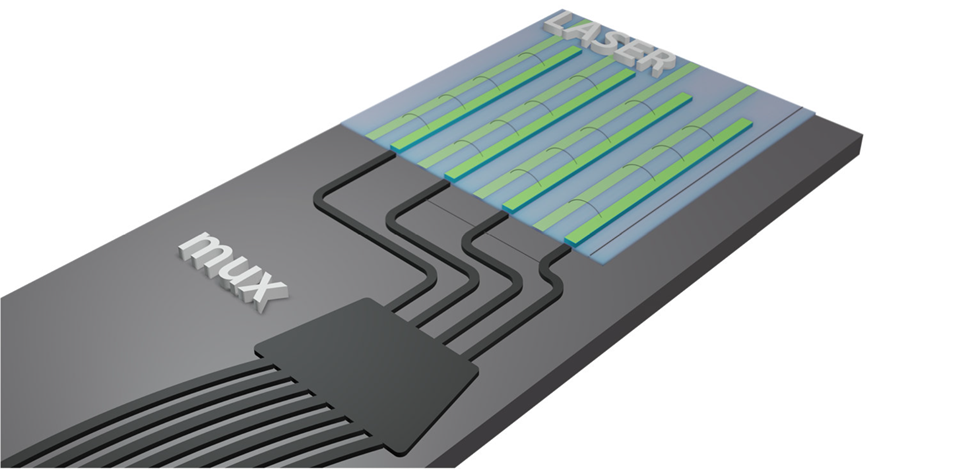

MILADO is dedicated to creating a groundbreaking platform for the cost-effective and large-scale production of mid-infrared (MIR) lasers. At the heart of MILADO is the innovative technology upscale of Quantum Cascade Laser (QCL) epitaxy on large-area substrates and the pioneering development of direct III-V epitaxy on silicon. By integrating QCL and Si-based MIR photonics using Complementary Metal Oxide Semiconductor(CMOS)-based technology, MILADO merges III-V and silicon photonics technologies. This versatile platform will revolutionize markets by enabling new sensors for personal medical diagnostics and edge-sensors in chemical production